MUD AID™

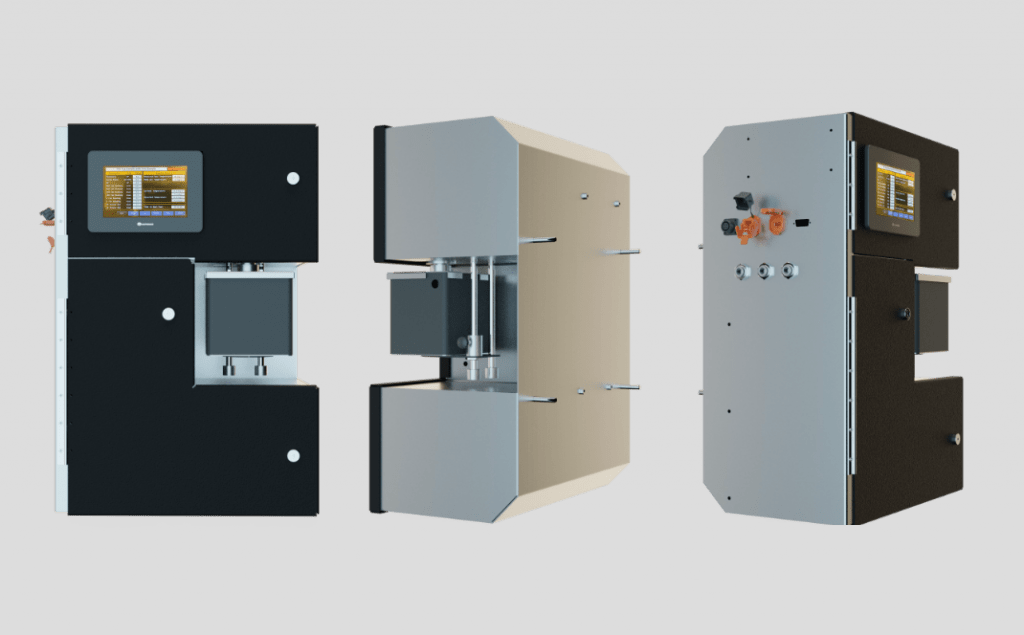

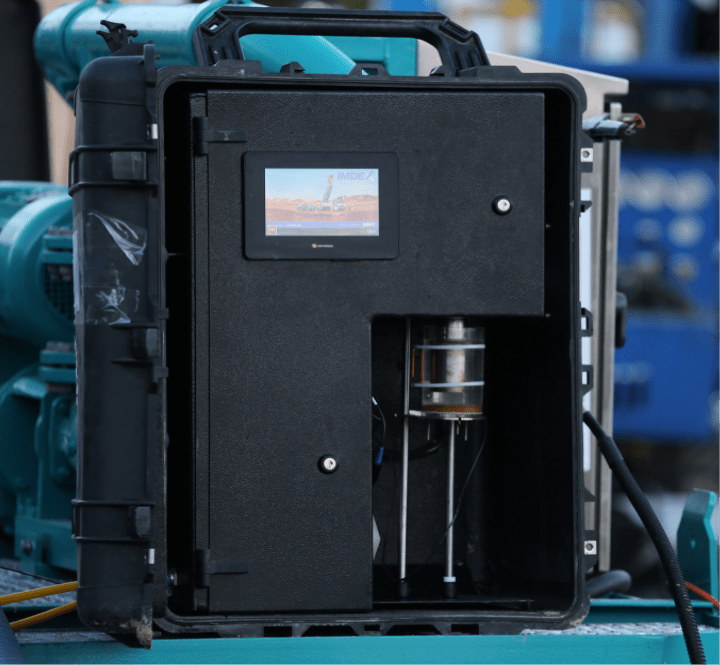

When a drilling fluids specialist cannot be on-site full-time, an automated system can be beneficial to measure and monitor drilling fluid properties. The newly launched MUD AID™ is a remotely monitored, automated in-field diagnosis unit, designed to manage and automate drilling fluid processes.

The MUD AID™ facilitates the optimization and execution of the drilling fluid program by presenting real-time information on fluid properties. This complements the job of the drilling fluids specialist and may assist in optimizing drilling fluid performance. The unit live-samples drilling fluid and tests project-specific properties, to API standards where applicable. The unit presents this data in real-time allowing the operator to make adjustments according to the program.

The MUD AID™ is integrated with the winning, secure, cloud-based web portal IMDEXHUB-IQ™, for complete visibility anywhere, anytime across the operation.

Features

- Increased productivity – Real-time notification of drilling fluid parameters and support from a qualified drilling fluids specialist, anywhere, anytime in the world

- Reduced downtime – Standard tests at regular intervals help identify issues as they occur

- Safety – Reduced risks associated with personnel/contractors on site

- Instant decision making – Having access to information means decisions can be made in a timely matter and provides accountability on performance

- Safety – Reduced risks associated with personnel/contractors on site

- Instant decision making – Having access to information means decisions can be made in a timely matter and provides accountability on performance

- Reporting – Automatically generated daily drilling fluid reports and recaps

- Secure chain of custody of the data with seamless workflows.

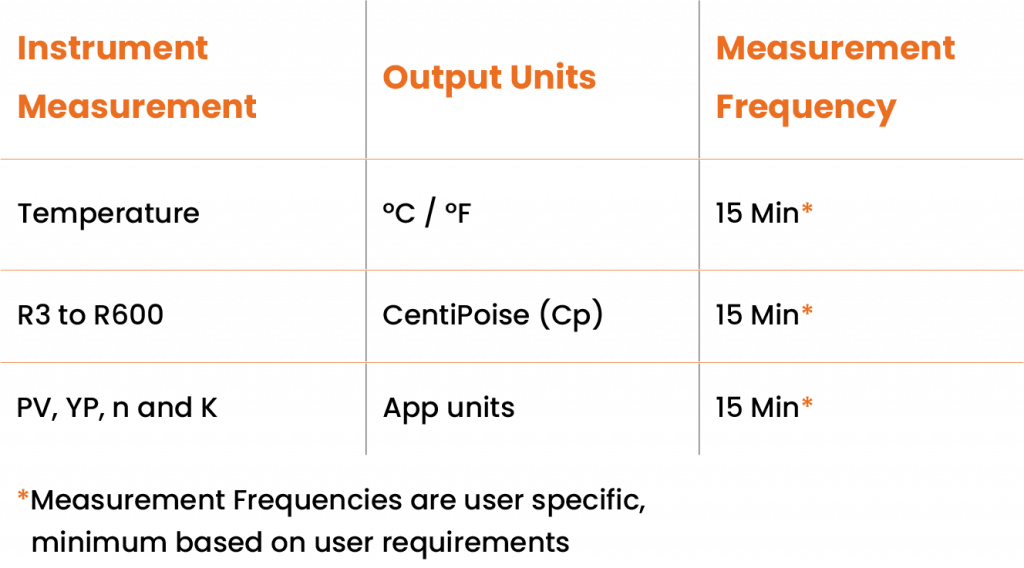

Measurements & Outputs

Easy Setup & Customization

The MUD AID™ is portable, lightweight and easy to install and operate. Set up includes pairing the MUD AID™ to site specific conditions, setting parameters and automating alerts, and helping to intercept any potential issues.

The drilling fluid specialist will remotely provide periodic monitoring and recommendations, so drillers can attempt to rectify variances in the system – providing drillers greater control over their drilling fluid system.

Drilling fluid test properties are viewed through the IMDEXHUB-IQ™ as well as on the unit display, which provides instant, secure access to real-time data and historical information. Data can also be downloaded via USB.

Instant Access to Data, Anywhere, Anytime

IMDEXHUB-IQ™ collects, stores and provides critical operational data, protected through a validated chain of custody and secure database. This award winning, secure, cloud based web portal can be accessed from any internet connection.

IMDEXHUB-IQ™ provides efficient data work flow and real-time secure access to information, such as data from REFLEX tools, shift reports, pre-starts and more, for geologists, drill supervisors and other key decision makers.

Specifications

- 24/7 tracking of drilling fluid parameters (Ability to be programmed to testfrom every 30 mins to every 12 hrs)

- Programmed monitoring of individual drilling fluid programs, to intercept potential issues before they become major

- Trend tables for collected data

- Email alerts when parameters are breached

- Integration with IMDEXHUB-IQ™, providing access to real-time data and historical information for decision makers

- Up to 60 days storage capacity of drilling fluids tests (With full history available via IMDEXHUB-IQ™)

- Access data and reports on site via any VNC application (from PC, cellphone, or tablet), or output stored data via USB

- Portable, lightweight design – Two pelican cases 45kg and 30kg

- Easy 30 min installation time and easy operation

- Can be integrated with PASON / WITS0 systems

- Wi-Fi, 3G/4G, LTE with satellite fail-over connectivity

- Can be powered via multiple power options (220VAC, 110VAC, 24VDC rigpower, 24VDC solar/battery)

Testing Capabilities

- Rheology: 0 – 600 rpm, Plastic Viscosity, Yield Point, Gels, Apparent Viscosity

- Temperature

- Temperature

- Ions: pH, Chlorides, Potassium, Calcium, others available

- Density / Mud Weight