OLR

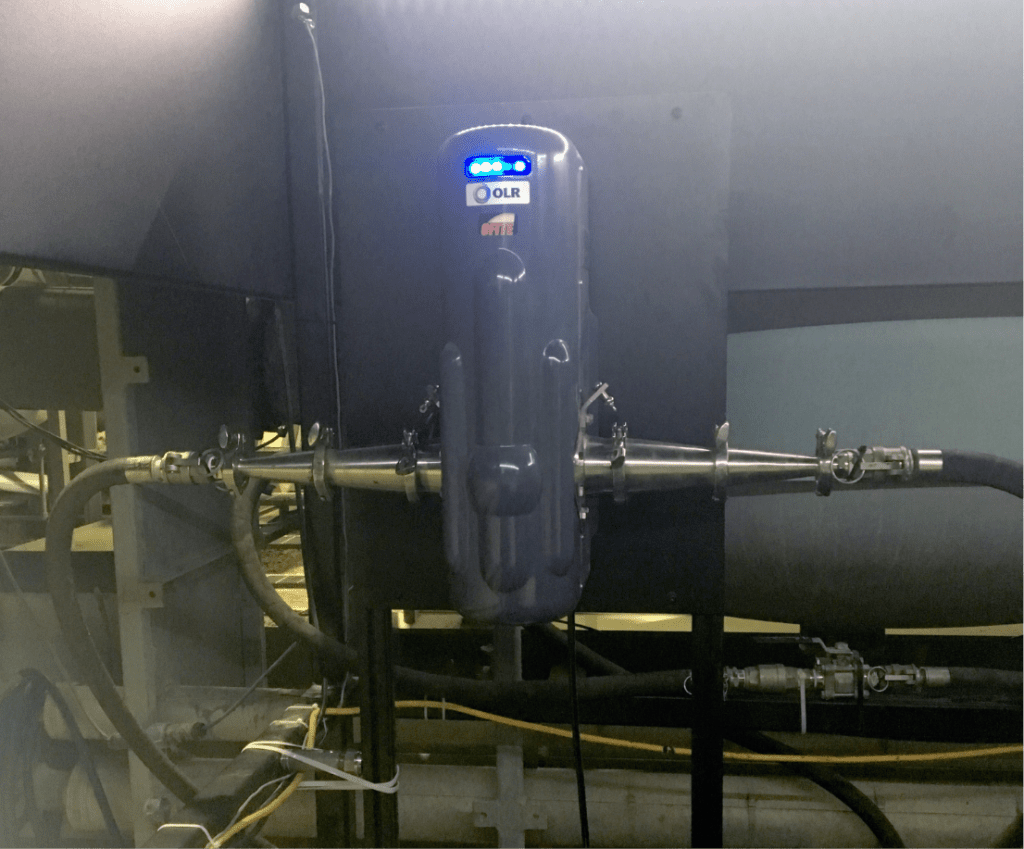

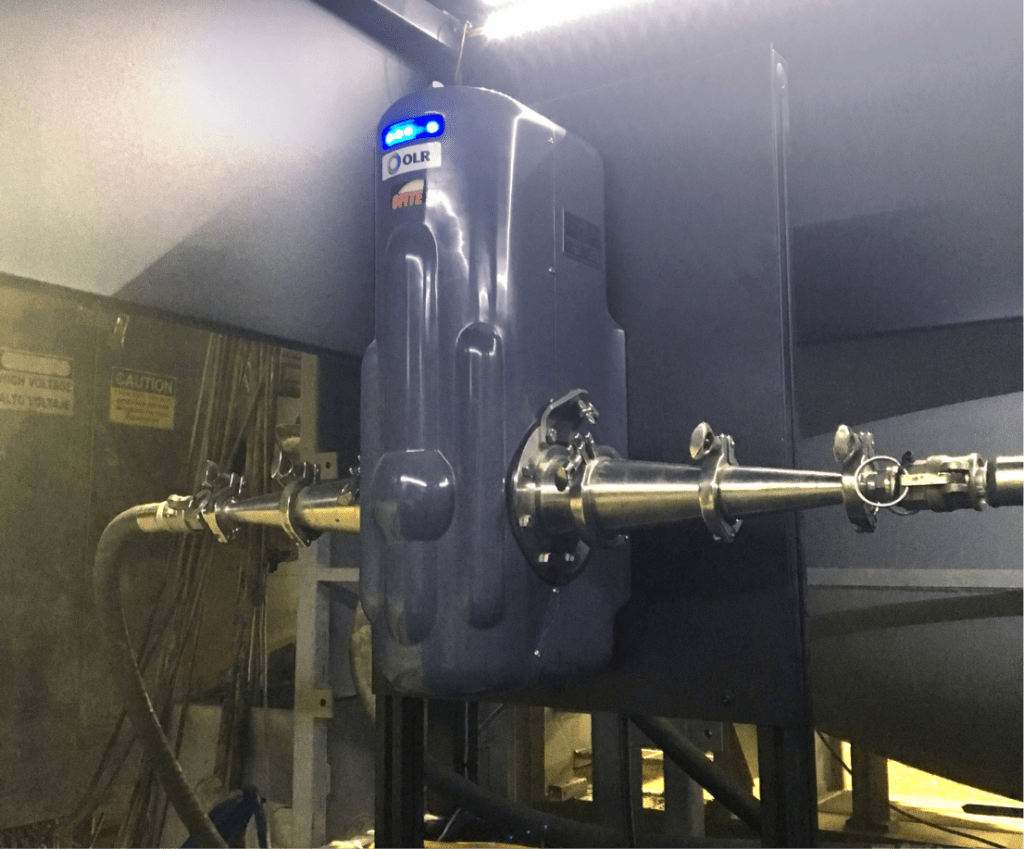

The OnLine Rheometer (OLR) is designed to continuously measure, plot, and report the rheological properties of drilling, completion, and fluids within a system.

The OLR uses a squeezeflow technique; it measures storage and loss moduli by imposing a small cyclic deformation on a liquid sample at a variety of frequencies, from 1-100 Hz. Quality control parameters and user interface are based on η* (complex viscosity [Pa s]), as measured by the OLR. The response of the liquid is measured and displayed in terms of G’ (storage modulus [Pa]), G” (loss modulus [Pa]), δ (phase angle [Degrees]), and η*.

US Patent 7,054,766 B2

Features

Fast and Reliable Real Time Results

Low Maintenance

Out of Specification Diagnosis

Plug-and-Play Installation

Precise and Robust Sensor System

Process Control

Process Monitoring

Quality Control

State of the Art Technology

Time and Cost Savings

Specifications

• Frequency Range: 1 – 100 Hz

• Viscosity Measurement Range (geometry dependent): 0.25 – 200,000 Pa s

• Force Range: 0 – 44.48 N

• Operating Range:

• Temperature: 14° – 230°F (-10° – 110°C)

• Pressure: 0.7 – 145 psi (4.8 – 1,000 kPa)

• Temperature Measurement: RTD PT100 Ohm, Class A

• Size: 11.6″ × 18.1″ × 23.8″ (30 × 46 × 61 cm)

• Weight: 145 lb (65 kg)

Requirements

• Electrical:

• Input: 115 – 230 VAC, 50/60 Hz

• Output: 24 VDC

• Power Input Maximum: 10 W

• Fuses: 24V, 5A

• Suitable for 1″ to 8″ pipe (DN25 – DN200)

Software (SOLR) Features

Set-up of process monitoring and quality control parameters

Monitoring and control of process either through SOLR or through the factory PLC

Out-of-specification product diagnosis

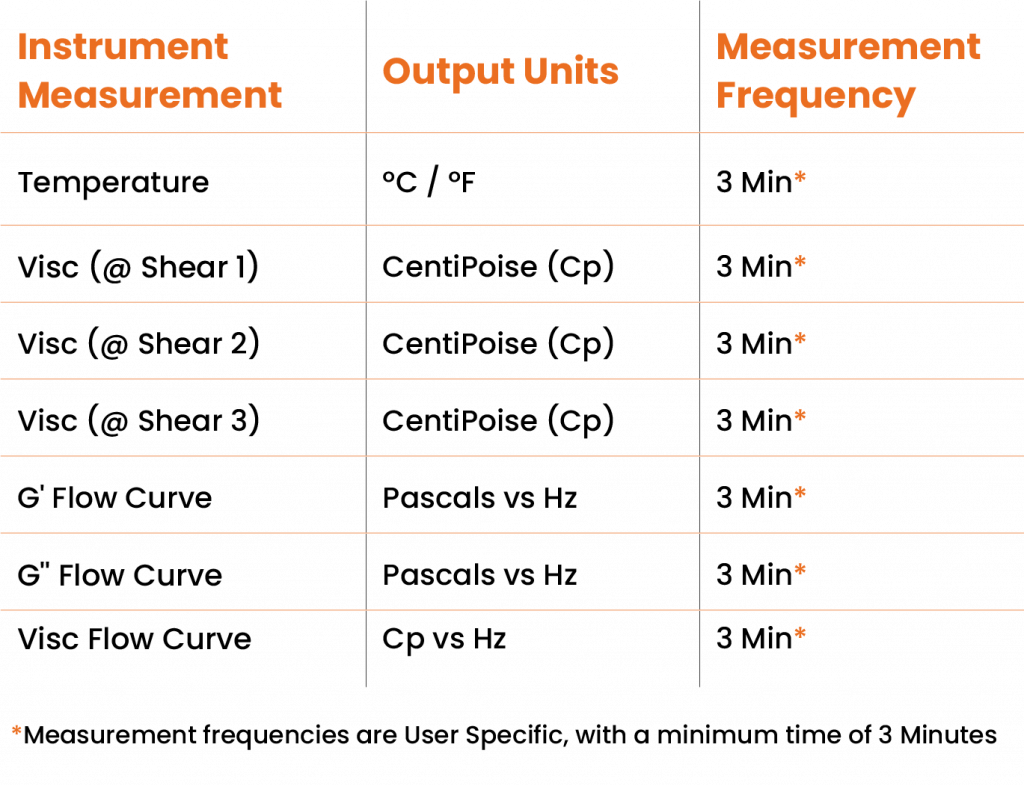

Measurements & Output

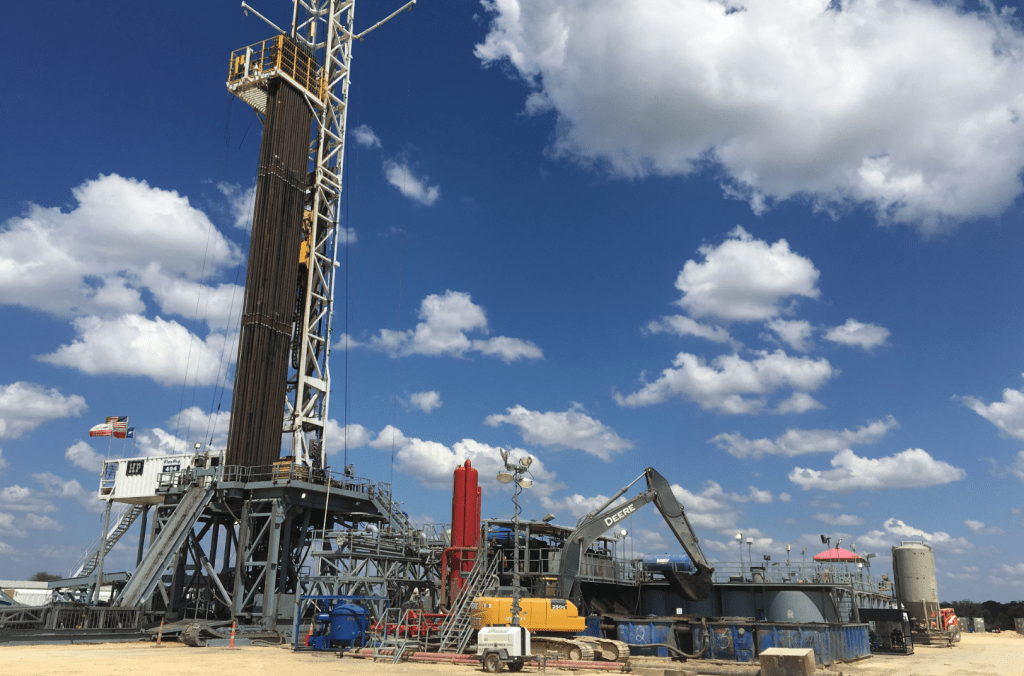

OASYS at the Rigsite

These technologies provide a wide range of measurement capability based on the critical requirements of fluid properties throughout the drilling process. The ability to capture these measurements in real-time is invaluable to any drilling operation focused on reducing cost, making informed decisions, gaining efficiencies, increased safety, and ultimately increased profitability to name a few the benefits. The modular package allows clients to choose what measurements are critical for their operation in order to address challenges specific to their operation. The system is capable of integrating with multiple rig systems which allows for data transfer and storage seamless for further analysis and evaluation.

OLR in Food Products

The new OnLine Rheometer (OLR) measures the flow properties of domestic chemical products in the process pipe so products remain in specification.

The OnLine Rheometer offers to the world market the first OnLine Rheometer (OLR) to continuously measure, plot and report the flow properties of liquids in process pipes. The OLR assist process monitoring, process control and quality control of liquids in the process and manufacturing of food products.

Flow properties that influence processability or mouthfeel like viscosity, tack, elasticity, body and others are important for a variety of products in the food industry. The OnLine Rheometer (OLR) is able to make measurements that directly relate to these variables and provide feedback to the operator in real time. In this way the operator can make informed process decisions about the quality of the material in the pipe and make changes as appropriate.

The OLR can reduce or remove costly waiting times associated with laboratory testing, removing production bottlenecks and increasing effective production capacity. In addition consumer-critical parameters such as mouthfeel can now be monitored on-line so that customer satisfaction with the final product can be better assured during production rather than post production from a taste panel assessment. The OLR will consistently measure the properties that define critical mouthfeel attributes that have been previously evaluated as preferred and important from pilot product tests with taste panels.

In many liquid food formulations, attributes like tack, elasticity, mouth-feel etc arise due to microstructural phenomena that occur over a time scale ranging between a few milliseconds and a few seconds and a length-scale that spans a few microns to a few millimetres. Unfortunately typical process viscometers operate at frequencies much higher than those required to access the information relevant to the attributes of interest. Therefore, it is often difficult (and sometimes impossible) to correlate the measurements of typical process viscometers to properties that are of interest to the process/production engineer. The OLR however is tuned to frequencies that probe the relevant microstructure and in doing so provides measurements that can be more easily correlated to the attributes of interest. Additionally the software for the OLR, SOLR, allows the process/production engineer to select a range of frequencies (three maximum) and monitor the measurements at these frequencies over the course of the production process – in real-time. Once a signature of a good product is set, the process can be controlled /monitored so that products remain in spec for all subsequent batches.

- Fast and reliable real time results

- Low maintenance

- Out-of-specification diagnosis

- Plug-and-play installation

- Precise and robust sensor system

- Process control

- Process monitoring

- Quality control

- State of the art technology

- Time and cost savings

The OLR provides a greater quantity and quality of information compared with most current technologies. The data from the OLR is instantaneous, removing the need for time-consuming laboratory analysis, thereby reducing production costs and bottlenecks incurred from waiting for QC results

KEY BENEFITS

The OLR Reduces Costs, Minimizes Downtime and Increases profitability.

OLR in Chemical Products

The new Online Rheometer (OLR) measures the flow properties of domestic chemical products in the process pipe so products remain in specification.

The OnLine Rheometer offers to the world market the first OnLine Rheometer (OLR) to continuously measure, plot and report the flow properties of process liquids in the pipe. The OLR is for process monitoring, process control and quality control of liquids in the process and manufacturing of chemical products.

Pourability, viscosity , spread ability, tack, elasticity and other textural or flow properties are important for a range of diverse products in the production and manufacture of domestic chemicals like detergent gels, crèmes, soaps and fabric conditioners. Product effectiveness and end-user experience is often driven by these variables which are in turn derived from the flow properties of the product during the production process. The ability to produce a material efficiently and effectively (processability) can also have a large impact on the viability of the end product. The OnLine Rheometer (OLR) is able to measure flow properties directly related to these variables in the pipe during the production process and feed data directly to the operator in real time. In this way the operator can make informed process decisions about the quality of the material in the pipe and make changes as appropriate to streamline the process.

The OLR can reduce or remove costly waiting times associated with laboratory testing, removing production bottlenecks and increasing effective production capacity. In addition consumer-critical parameters can now be monitored on-line so that customer satisfaction with the final product can be better assured.

Commercial process viscometers that are typically used in the industry exert high deformation rates that are not suitable for characterizing the micro-structural features in complex chemical formulations like gels, crèmes and fabric conditioners. Therefore micro-structure-dependent product- attributes like spread ability, tack, elasticity etc cannot usually be characterized by the real-time measurements made using available process viscometers and QC protocols that are based on these measurements are seldom effective. The OLR, however, is set-up such that the engineer/operator can better correlate the measurements to the critical attributes of the product like the ones mentioned above. Moreover, the OLR offers measurements over a range of frequencies (deformation-rates) and allows the engineer/operator to choose the measurements most relevant to the product. It also offers a more thorough insight into the rheology of the product being processed including the shear-thinning nature of the product.

- Fast and reliable real time results

- Low maintenance

- Out-of-specification diagnosis

- Plug-and-play installation

- Precise and robust sensor system

- Process control

- Process monitoring

- Quality control

- State of the art technology

- Time and cost savings

The OLR provides a greater quantity and quality of information compared with most current technologies. The data from the OLR is instantaneous, removing the need for time-consuming laboratory analysis, thereby reducing production costs incurred from waiting for QC results. The OLR provides an agile response to out-of-specification product and increases the effective production capacity of plant.

The OLR measures the viscoelastic properties of a process fluid in real time and will improve product quality and reduce wastage and saves time and therefore reduces processing costs.

OLR IN Cosmetic and Personal Care Products

The new Online Rheometer (OLR) measures the flow properties of domestic chemical products in the process pipe so products remain in specification.

The OnLine Rheometer offers to the world market the first OnLine Rheometer (OLR) to continuously measure, plot and report the flow properties of process liquids in the pipe. The OLR is for process monitoring, process control and quality control of liquids in the process and manufacturing of cosmetic and personal care products.

Skin-feel, elasticity, spread ability, tack and other textural or flow properties are important for a diverse range of products in the cosmetic, cosmeceutical and pharmaceutical industries. The end-user experience is most often driven by the above variables which can in turn be traced back to the flow properties of the product during the production process. The ability to produce a material efficiently and effectively (processability) can also have a large impact on the viability of the end product. The OnLine Rheometer (OLR) is able to measure flow properties directly related to these variables in the pipe during the production process and provide real time feedback to the operator. In this way the operator can make informed process decisions about the quality of the material in the pipe and make changes as appropriate to streamline the process.

The OLR can reduce or remove costly waiting times associated with laboratory testing, removing production bottlenecks and increasing effective production capacity. In addition rheology related consumer-critical parameters can now be monitored on-line so that customer satisfaction with the final product can be better assured.

Commercial process viscometers that are typically employed in the industry deform the process fluid at very high rates and therefore elicit (and measure) a response that is sometimes not suitable for characterizing the micro-structural features in complex cosmetic formulations. Therefore micro-structure-dependent product- attributes like “skin-feel” and “body” are usually not characterized by the real-time measurements made using available process viscometers and QC protocols that are based on these measurements are seldom effective. The OLR, however, is set-up such that the engineer/operator can better correlate the measurements to the critical attributes of the product like the ones mentioned above. Moreover, the OLR offers measurements over a range of frequencies (deformation-rates) and allows the engineer/operator to choose the measurements most relevant to the product. It also offers a more thorough insight into the rheology of the product being processed including the shear-thinning nature of the product.

- Fast and reliable real time results

- Low maintenance

- Out-of-specification diagnosis

- Plug-and-play installation

- Precise and robust sensor system

- Process control

- Process monitoring

- Quality control

- State of the art technology

- Time and cost savings

The OLR provides a greater quantity and quality of information compared with most current technologies. The data from the OLR is instantaneous, removing the need for time-consuming laboratory analysis, thereby reducing production costs incurred from waiting for QC results. The OLR provides an agile response to out-of-specification product and increases the effective production capacity of plant.

OASYS can benefit any business requiring realtime fluid monitoring including:

Oil & Gas

Cosmetics

Production

Chemical

Mining

Pharmaceutical

Wastewater

Polymer

Personal Care

Surface Coatings and Paint